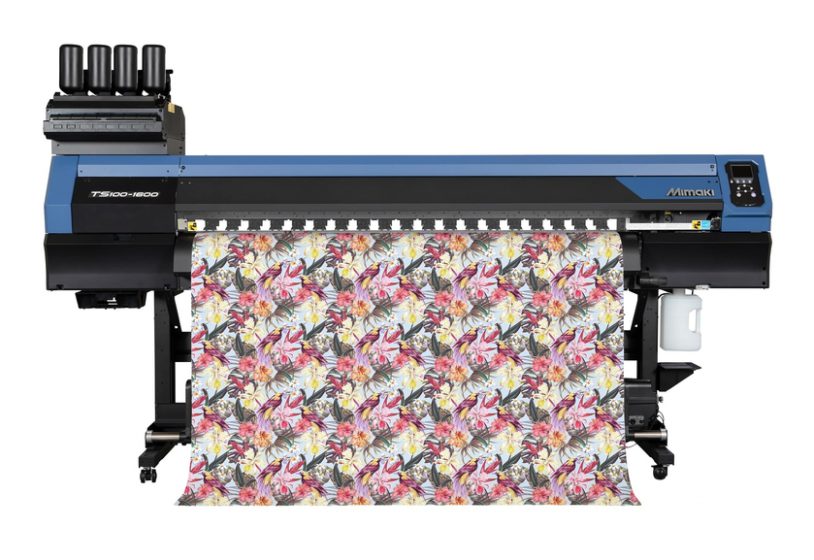

New Year, New Technology. The TS100-1600 is Mimaki’s latest addition to its ‘100 series’ portfolio. This affordable, high-quality system is ideal for printers looking to add their first digital sublimation printing solution or expand their production capacity.

Bert Benckhuysen, Senior Product Manager at Mimaki Europe explained, “The textile printing industry has seen a growing requirement for increased product variety, lower inventories and shorter delivery times. Add to that the economic challenges of 2020 and we recognized that the market needed a digital textile printer that combined high quality, on-demand output with a low initial investment and cost-effective production. Having seen the success of our 100 series printers for the same reasons in other sectors, we knew that introducing a textile printer to this range would provide our customers with an opportunity to expand their businesses and seek new revenue opportunities, even amid these challenging times.”

Available in the EMEA from April 2021, the TS100-1600 has a print width of 1,600 mm and speed of 70 m2/h in the fastest mode. In addition, the use of a 1 litre ink bottle helps reduce the running cost and enables stable, continuous operation due to the reduced need for ink replacement. The printer is also equipped with a variety of renowned Mimaki features, including NCU (Nozzle Check Unit)1, NRS (Nozzle Recovery System)2, and the DAS (Dot Adjustment System) function which automates dot position correction and feeding amount correction, reducing the need for operator intervention. While the RIP software RasterLink 7 comes as standard, printers purchasing the TS100-1600 can also choose to add the TxLink4, another one of Mimaki’s original RIP software platforms.

Mimaki Bompan Textile will have a TS100-1600 demo unit in its showroom at the end of February, while the new textile printer will be available in the EMEA region from April 2021.