Operating in the world of theatre and television and all aspects of the exhibition sector, Italian company Lu-Bek has specialised in the supply of large-scale technical fabrics for staging. By carefully selecting suppliers and using its internal know-how in the manufacturing of large-scale fabrics, the company has quickly established itself as a go-to partner and, within a few years, has managed to expand its business and catchment area. Its strengths lie in the high quality materials used – technical and functional fabrics – and the high standard of its customer service. With a view to further improving the latter, in 2019 Lu-Bek decided to take an important step forward, standing out from the competition by installing a digital printing system to bring fabric decoration and personalization in-house. Which printing technology and system were chosen? Large format digital sublimation printing and the Mimaki TS500P-3200 printer.

Staging fabrics specialist

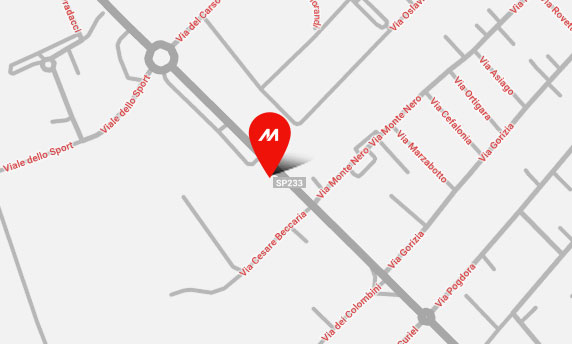

Based in Campi Bisenzio, in the province of Florence, Lu-Bek has been operating since 2013 as a company specialising in the production and distribution of large-scale fire-retardant fabrics for the exhibition, theatre, television and digital printing sectors. Over the years, the company has diversified its offer to include technical fabrics and curtains, false ceilings, projection and rear-projection screens and theatre backdrops. “Lu-Bek operates in a very specialised market segment, where it is essential to continue to innovate in order to remain competitive,” explains Luciano Borchi, founder and owner of Lu-Bek. “As fabric producers, we were already dealing with fabrics intended for digital printing, so we thought that the ability to print directly in house would allow us to further complete and enhance our offering”.

In spring 2019, Lu-Bek invested in Mimaki’s TS500P-3200 large format sublimation printer, combined with a calender from Italian supplier Monti, installed a few months later. “We began testing and experimenting straight away to work out the potential applications and our first experiences with digital printing were very positive. Although it was a new technology for us, Mimaki’s printer proved easy to manage and effective at meeting our needs.”

Investing in digital printing

According to Luciano Borchi, digital printing was a natural direction for the company’s business, so much so that the management had very clear ideas about what inkjet printing technology to focus on: “The demand for personalisation has continued to grow and very often involved minimal quantities. For us it was an opportunity to be seized and sublimation inkjet printing was the best option to manage the production of fabrics once printed, in the quality required. We explored a number of options and eventually opted for the Mimaki TS500P-3200 printer.”

Thanks to Mimaki’s large format sublimation printing, Lu-Bek has achieved its first goal, which is to expand the range of products to enter new relevant markets, primarily the interior decoration sector. In addition to enhancing technical fabrics with high-impact designs – and with the great advantage of not altering the technical properties of the fabrics by printing – the company has developed a series of impactful applications, including backlit displays, false ceilings, stretched ceilings (stretched fabrics to cover ceilings and walls); all particularly interesting solutions, with great appeal, both green and economical, for setting up in environments such as shops, hotels, restaurants, showrooms. Lu-Bek has also introduced new materials for innovative applications, including interior wallpaper.

The format of the Mimaki TS500P-3200 printer was undoubtedly one of the decisive factors in Lu-Bek’s choice of this technology: with this the company can in fact handle very large fabrics with extreme flexibility. There are also some other aspects that the management of the Florentine company appreciated: “Mimaki’s sublimation printing allows us to achieve very high quality, with brightly coloured prints, without altering the technical properties and feel of the fabrics, which is a fundamental requirement in our sector. Furthermore, the use of water-based inks brings further benefits, as the print is odourless and environmentally-friendly, as well as compatible with indoor applications,” explains Borchi.

“Today we are able to print and package fabrics in-house, which allows us to offer a complete, timely and accurate service. Thanks to sublimation printing, all transport, logistics and assembly operations are also simplified: the printed sheets are easy to handle and can be easily folded during transport. Being light and resistant, they are also easy to manage during assembly operations”.

Despite the digital department becoming fully operational at the same time as the COVID-19 pandemic broke out, Lu-Bek is using the new technology to develop innovative applications and look towards new markets: “Like many other companies, ours has also suffered the impact of the market shutdown caused by the COVID-19 pandemic. In January 2020, thanks to the new digital department, we were looking at hiring new resources, but obviously that plan was interrupted. Last year we suffered a decline in turnover and the first months of 2021 were also difficult. This hasn’t stopped us however and we are using digital printing to evaluate new opportunities, create innovative products and set-up solutions and initiate conversations with players in new markets, including interior decoration and clothing, to prepare ourselves to face the post-COVID period as best we can,” concludes Luciano Borchi.