An evolution of the Mimaki TX300P-1800, this new hybrid printer will enable textile and garment manufacturers unparalleled flexibility and enhanced application opportunities.

- New hybrid printer enables direct-to-textile or direct-to-transfer printing on entry-level printer

- Flexibility of press enables smaller print service providers to broaden applications and enter new markets

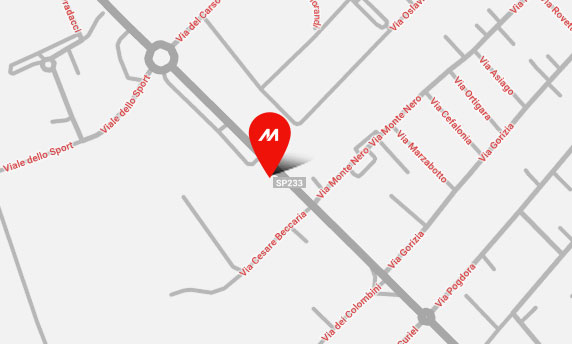

Mimaki Engineering, a leading manufacturer of inkjet printers and cutting systems, today announces the first global technology demonstration of a brand-new hybrid digital textile printer from the TX300P series at ITMA 2019 (Barcelona, Spain, 20-26 June, Booth B110, Hall 3). Uniquely featuring both direct-to-textile and direct-to-transfer print capabilities, the new printer achieves unparalleled flexibility in ink combinations and substrates – opening new profitable opportunities for businesses.

The new printer is an evolution of the Mimaki TX300P-1800, with the added capability of printing direct-to-transfer. Crucially, print service providers will benefit from enhanced versatility in terms of fabrics, applications and targeted markets. This affords smaller print service providers with an opportunity to provide a full range of textile printing applications with just one system. Aligned with Mimaki’s Total Solution Provider approach, the printer is compatible with Mimaki’s full range of pre-treating, steaming and washing equipment.

“The textile market is still relatively early-on in the adoption of digital printers, with most textiles being printed in the conventional way and a lot of large players dominating the market. With this new hybrid printer, Mimaki has provided an affordable solution that lowers the barriers to entry for smaller print providers,” says Ronald van den Broek, General Manager Sales EMEA. “For larger volume production houses, the printer is valuable for smaller runs and the myriad of benefits digital production provides.”

Interchangeable platens enable the hybrid nature of the printer. When printing direct-to-textile, excess ink that penetrates through the fabric is drained by a platen with an ink-receiving ditch. This can quickly be swapped out for a vacuum platen, suitable for printing onto heat transfer paper. The printer can also be configured with three different ink combinations, comprising textile pigment/direct sublimation, or textile pigment/sublimation transfer, or direct sublimation/sublimation transfer. This means more versatility and more possibilities, making it an ideal entry model.

Reliable productivity is assured with Mimaki Core Technology including a Nozzle Check Unit and Nozzle Recovery System. This enables the printer to automatically clean print heads when nozzles malfunction, and when nozzles are not repairable, and to also switch any missing or damaged nozzles with working nozzles without stopping production and without affecting final print quality. An adjustable head gap also means the distance from print head to substrate can be changed, preventing print heads from touching substrates.

“The features of this new hybrid printer will enable textile and garment manufacturers to achieve unparalleled flexibility and enhanced application opportunities for increased business growth. With this product, Mimaki is effectively democratising accessibility to textile printing, and with solutions like this in the market, we expect to see improved growth of digital printing in textiles,” van den Broek concludes.