The all-in-one textile solution

The ultimate solution for textile sampling or short runs on-demand printing

The TX300P-1800 MKII printer

Unique features

- Versatility in fabrics

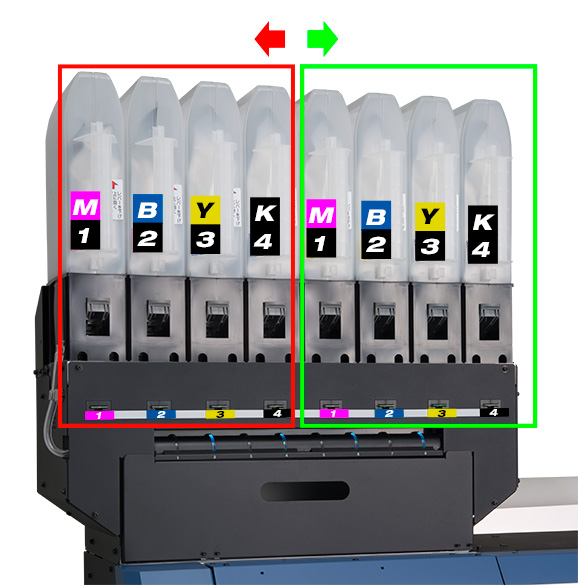

Hybrid printer, boasting both direct-to-textile and sublimation transfer print capabilities.This unique Hybrid printer can load 3 different dual ink sets at the same time, making it possible to print on sublimation transfer paper and direct-to-textile. A wide range of different fabrics and applications become possible with just one printer.

Hybrid printer, boasting both direct-to-textile and sublimation transfer print capabilities.This unique Hybrid printer can load 3 different dual ink sets at the same time, making it possible to print on sublimation transfer paper and direct-to-textile. A wide range of different fabrics and applications become possible with just one printer.

With 5 dedicated direct-to-textile ink sets, this printer can cover all possible applications for direct printing.

Hybrid functionality ink settings

Sb420 Bl, M, Y, K – TP400 C, M, Y, K

Sb411 Bl, M, Y, K – TP400 C, M, Y, K

Sb420 Bl, M, Y, K – Sb411 Bl, M, Y, K

- Flexibility in technology

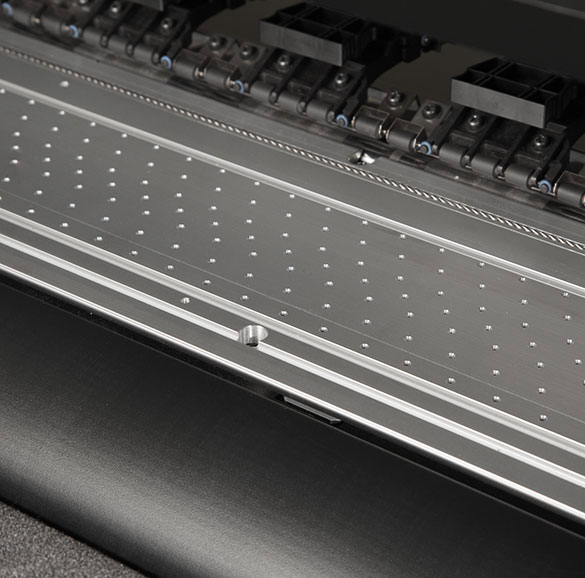

Unique in the textile printing market today is the possibility to change from direct printing to sublimation paper printing by installing an easy-to-click vacuum platen.When printing direct-to-textile, the excess ink penetrated through the fabric is drained by an ink-receiving channel.

Unique in the textile printing market today is the possibility to change from direct printing to sublimation paper printing by installing an easy-to-click vacuum platen.When printing direct-to-textile, the excess ink penetrated through the fabric is drained by an ink-receiving channel. When printing on heat transfer paper however, a vacuum platen can easily be clicked-on, needed for paper printing to prevent the paper from cockling.

When printing on heat transfer paper however, a vacuum platen can easily be clicked-on, needed for paper printing to prevent the paper from cockling.

- Unique high head gap

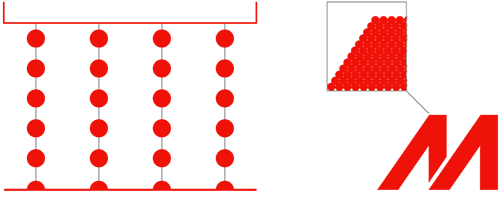

Accurate dot placement even when using a higher print head gap.With unstable fabrics or thin paper, we want to prevent the print heads from touching the media. Mimaki has developed its own waveform for the print heads to fire ink drops at a faster speed. Therefore, it is possible to lift the print heads up to 7mm high, which still results in a high print quality.

Accurate dot placement even when using a higher print head gap.With unstable fabrics or thin paper, we want to prevent the print heads from touching the media. Mimaki has developed its own waveform for the print heads to fire ink drops at a faster speed. Therefore, it is possible to lift the print heads up to 7mm high, which still results in a high print quality.

TX300P-1800 MKII

Ink drops are fired straight even with a high head gap, which results in an accurate dot placement ensuring sharp edges.

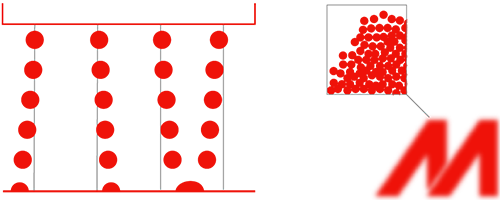

Older generation printer

Ink drops deviate by high head gap printing, which results in inaccurate dot placement causing blurry edges and grainy appearances.

Designed to produce a wide range

of materials and applications

Soft Signage, Sports Apparel, Wallpaper, Posters and more.

Versatility in inks

thanks to unique hybrid technology

The TX300P-1800MKII offers a unique opportunity with all available textiles inks possible for basically every application in textile printing. Mimaki is offering a total of 10 different ink sets including 3 dual ink configurations to even broaden the range of applications. Available ink types include: Reactive (RC400), Acid (AC400), Pigment (TP400), Disperse (DD400), Direct Sublimation (SB420) and Paper Transfer Sublimation (SB411).

Choose pigment inks to create home textile and fashion with cotton and linen fabrics. Go for sublimation inks to create sportswear, softsignage, fashion and home textile on polyester fabrics. Choose disperse disperse for superior fastness by applying high temperature fixation on polyester, nylon and acetate to create flags, industrial textile, home textile and high-end fashion. Or go for reactive of acid inks if you want to achieve vivid colours.

For even more confidence

our inks are OEKO-TEX certified

Mimaki inks Sb411 and Sb420 for the TX300P-1800 MKII are OEKO-TEX® certified. ECO PASSPORT by OEKO-TEX® is a mechanism by which textile chemical suppliers demonstrate that their products are suitable to print skin-friendly clothing and other textiles for end users.

This certificate therefore constitutes an important decision-making element when purchasing inks for textile production.

This printer includes Mimaki Core Technologies that offer the best print quality, maximum productivity and reduced exposure to risks that can delay production. See below list of core technologies that are included in the TX300P-1800 MKII.

For continued productivity

- Nozzle Check Unit (NCU), to detect missing nozzles

- Nozzle Recovery System (NRS), to replace missing nozzles

- Mimaki Ink Bulk System (MBIS3), for scalability to higher ink capacity

- Uninterrupted Ink Supply System (UISS), for continued replenishment

- Automatic Media Feeder (AMF), for optimum media tension

- Automatic Cleaning Function, to keep the print head clean

- Automatic Wiper Cleaner, to keep the wiper clean

- Jam Sensor, to prevent print head damage

For quality printing

- Mimaki Advanced Pass System (MAPS4), to reduce banding

- Waveform Control (WFC), for best possible image sharpness

- Variable Dots Technology (VDT), for smoother gradations

- Mimaki Fine Diffusion (MFD), for smoother colours

| Model | TX300P-1800 MkII (Fabrics Media) | TX300P-1800 MkII (Transfer Paper) | |

|---|---|---|---|

| Print head | Method | Drop-on-demand piezoelectric print heads | |

| Specification | 4-Head Inline | ||

| Drop size | From 6pl to 24pl | ||

| Printing mode (scan x feed) | 540 x 360 dpi / 540 x 540 dpi / 540 x 720 dpi / 720 x 720 dpi / 720 x 1080dpi / 720 x 1440 dpi | ||

| Usable inks | Sublimation dye ink: Sb420, Textile pigment ink: TP400, Disperse dye ink: Dd400, Acid-dye ink: Ac400, Reactive-dye ink: Rc400, Rc500, Sublimation dye Transfer ink: Sb411* | ||

| Usable media | Polyester, cotton, silk etc. (Except the expansion and contraction media) | Transfer paper | |

| Max. printing width | 1,920mm (75.6 in) | 1,940mm (76.4 in) | |

| Model | TX300P-1800 / TX300P-1800 MkII (Fabrics media) | TX300P-1800 MkII (transfer paper) | ||

|---|---|---|---|---|

| Roll Media size | Maximum | 1,920mm (75.6 in) | 1,950mm (76.8 in) | |

| Minimum | 210mm (8.3 in) | 210mm (8.3 in) | ||

| Thickness | 1.0mm or less (0.039 in or less) | |||

| Printing surface | Regardless of faces in and out | Side facing outward | ||

| Feed | Roll outside diameter | Φ 250mm or less (Φ 9.8 in or less) | ||

| Roll weight | 40kg or less (88.2 lb or less) | |||

| Roll inside diameter | 2 or 3 inches | |||

| Take-up | Roll outside diameter | Φ 250mm or less (Φ 9.8 in or less) Media edge Guide: Φ200mm (Φ7.87 in) or less. | ||

| Roll weight | 40kg or less (88.2 lb or less) | |||

| Roll inside diameter | 2 or 3 inches | |||

| Distance accuracy | Absolute accuracy | Whichever the larger one of ±0.3mm or ±0.3% of the designated (whichever the larger one of ±0.01 in or ±0.3% of the designated) | ||

| Reproducibility | Whichever the larger one of ±0.2mm or ±0.1% of the designated (whichever the larger one of ±0.008 in or ±0.1% of the designated) | |||

| Perpendicularity | ±0.5mm / 1,000mm (±0.02 in / 39.4 in) | |||

| Media skew | 5mm or less / 10m (0.2 in or less / 32.8 ft) | |||

| Head height adjustment | 2mm to 7mm, can be freely adjusted manually (0.08 in to 0.28 in, can be freely adjusted manually) | |||

| Waste ink tank | Bottle type: 2,000 cc (2 liters) x 2 | |||

| Interface | Print data transmission function | USB 2.0, Ethernet 1000BASE-T | ||

| Noise | during standby | Standby: 58 dB or less; during printing: 65 db or less | ||

| Safety Standard | VCCI-Class A, FCC-Class A, UL 60950, CE Marking (EMC, Low Voltage Directive, Machinery Directive, RoHS Directive), CB Report, REACH, Energy Star, RCM, and EAC | |||

| Power | AC 100 -120 V/ 200 -240 V 12 A/8 A 50/60 Hz | |||

| Power consumption | 1,440 W (AC 100 -120 V), 1,920 W (AC 200 -240 V) | |||

Software RIP

Mimaki’s own developed software RIP Rasterlink6Plus comes in the box.

Rasterlink6Plus

TxLink4 (optional)

Sb411

Paper Transfer Sublimation ink

Sb411 produces bright and vivid colours with good light-fastness and extreme good rub- and wash-fastness. Fixation by heat with calendar or flat heat press.

Packaging

Colour

Ink type

Sb420

Direct sublimation ink

Produces colours with high wash-fastness and durability and excellent light-fastness for outdoor applications. Fixation by Heat with calendar or heart fixation unit.

Packaging

Colour

6 colours: Bl M Y K Lbl Lm

Ink type

Dd400

Disperse dye ink

DD400 produces colours with high light- and wash-fastness and extreme durability. Finishing by pressurised steamer and washer.

Packaging

Colour

Ink type

TP400

Pigment ink

TP400 produces colours with high light- and wash-fastness. Fixation by heat with calendar or fixation unit.

Packaging

Colour

7 colours: C M Y K Bl Rd Lk

Ink type

Rc400

Reactive ink

Rc400 produces bright and vivid colours, and has high wash- and light-fastness. Finishing by steamer and washer.

Packaging

Colour

Ink type

Ac400

Acid ink

AC400 produces bright and vivid colours, has a high wash-fastness and durability, and has a very high light-fastness. Finishing by steamer and washer.

Packaging

Colour

Ink type

Request more information

Request a Virtual Demo

Webinar: Introducing the brand new TX300P all-in-one textile solution

Brochures