TS300P-1800

A new generation high-speed dye sublimation textile printer

Developed specifically for the textile print industry, the revolutionary new Mimaki TS300P-1800 delivers cost effective dye sublimation printing while maintaining high quality and high productivity. Perfectly suited to the creation of fashion, apparel, sportswear, furnishings and PoS, the TS300P-1800 uses state-of-the-art technology to set new performance benchmarks for the sector.

|

|

|

|

|

|

Create…

Fashion and Apparel, Sportswear, Home Furnishing and Upholstery Fabrics, Soft signage, Textile retail, PoS, Exhibition Graphics, Wall art and Much more…

Specifications of TS300P-1800

| Printhead | On-demand piezo head (4 in-line printheads) | |

| Print resolution | 360dpi, 540dpi, 720 dpi, 1080 dpi | |

| Maximum print width | 1,940 mm (76.4 in) | |

| Maximum media width | 1,950 mm (76.8 in) | |

| Ink | Type/Color | Sb410(Bl,M,Y,K,Lbl,Lm) |

| Package size | 2L Ink pack | |

| Media thickness | 1.0 mm or less | |

| Rolled media weight | 40 kg (88 lb) or less | |

| Certifications | VCCI class A, FCC class A, ETL UL 60950-1CE Marking (EMC, Low voltage, Machinery directive, and RoHS), CB, REACH, Energy Star, CCC, RCM |

|

| Interface | USB 2.0 Hi-speed / Ethernet 1000BASE-T | |

| Power supply | Single-phase AC100 – 120V / AC200 – 240V | |

| Power consumption | (AC100V)1.44kW / (AC200V)1.92kW | |

| Operational environment | Temperature: 20 – 30 °C ( 68 – 86 °F )Humidity: 35 – 65% Rh (Non condensing) | |

| Dimensions (W × D × H) | 3,200 × 850 × 1,857 mm (126 x 33.4 x 73 in ) | |

| Weight | 213 kg (469.6 lb) | |

Features of TS300P-1800

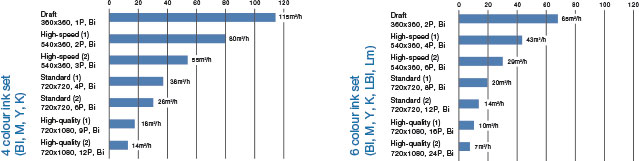

Maximum print speed of 115m2/h for high productivity

The TS300P-1800 optimizes the printing speed and quality to produce the desired print results. For this purpose, it provides a wide range of printing modes, from the draft printing mode (which operates at the maximum speed of 115m2/h) to high-quality printing mode

‘Cockling’ reduction features

TS300P-1800 incorporates a number of innovative new features to reduce the effects of ‘cockling’ (the wrinkling of the media surface due to high levels of ink absorbtion, which is particularly prevalent where low-cost or thin transfer papers are being used).

- High-gap print head with high accuracy ink drop placement ensures clear, sharp print

- Vacuum media hold-down system, smooths out cockling effects by using vacuum suction beneath the platen

- Larger media press plates reduce media uplift immediately after printing

- Auto Media Feeder (AMF) maintains stable media feeding and take up by automatically applying the correct tension

New Sb410 High Performance Ink Sets

- Reduced cost significantly improves profitability

- Improved ink resolvability and stability ensures better ink flow and jetting with easier and less frequent cleaning of nozzles required

- Low-sedimentation formulation delivers beautiful, vibrant, high-density printing

- Low smoke emission is beneficial for the work environment and improves production efficiency

- Mimaki Bulk Ink System 3 (MBIS3) utilises large 2 litre ink packs to deliver profitable long-run continuous print

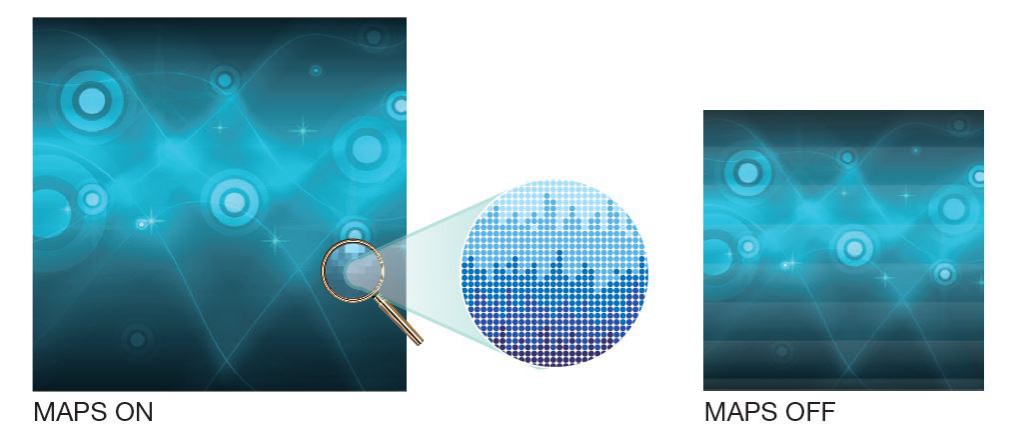

MAPS4 Advanced Pass System

MAPS is Mimaki’s unique anti-banding feature. To prevent banding, swath boundaries are overprinted and boundaries prone to banding are printed with fewer ink droplets.

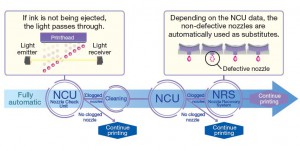

Continuous Uninterrupted Printing Features

In the event of a nozzle malfunction not being repairable by the use of the maintenance function, printing can continue by the use of another nozzle, without any loss of productivity or a reduction in image quality.

Uninterrupted Ink Supply System (UISS)

Two ink packs per colour can be set with the UISS function. When an ink bottle runs out, another bottle of the same colour automatically starts supplying ink.

Sophisticated RIP software maximizes the performance of TS300P-1800

A choice of RIP software is included:

- More beautiful and advanced print results are achieved by following a user-friendly interface that is easy to operate

- Colour replacement function enhances the ability to re-create printed images

- Print colour can be simulated on Illustrator / Photoshop without an actual print *This function requires MPM2 (Mimaki Profi le Master 2)

- Program update and profi le download can be easily performed via internet

Professional software RIP for multi colour separation TxLink 3 Lite

- Spot colour can be assigned to each colour on separation plates

- ICC profi le creation from CMYK + spot colours

- Colour replacement on raster data

- A variety of panelling functions, including step-and-repeat layout, which are useful for textile designing

Downloads

Brochure