Tiger-1800B MkIII

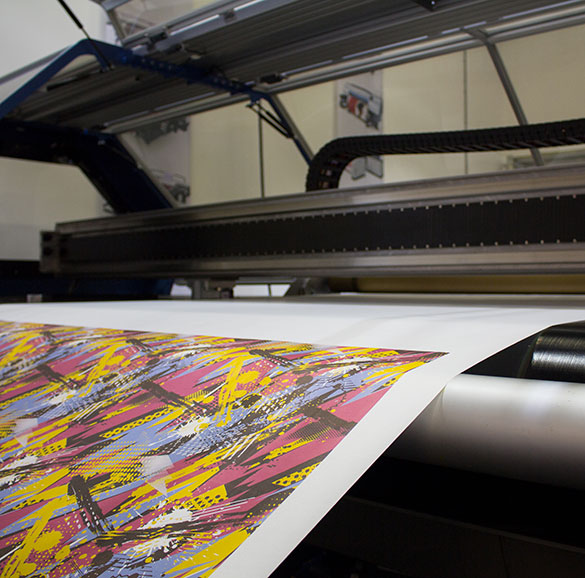

High speed textile inkjet printer with belt conveying system

The Tiger-1800B MKIII printer

Unique features

- High print quality

with MAPS4, even with 1 pass printing at 385 sqm/h.Thanks to Mimaki’s most advanced anti-banding system, MAPS4, even with 1-pass printing, beautiful output can be achieved for most applications.

with MAPS4, even with 1 pass printing at 385 sqm/h.Thanks to Mimaki’s most advanced anti-banding system, MAPS4, even with 1-pass printing, beautiful output can be achieved for most applications.

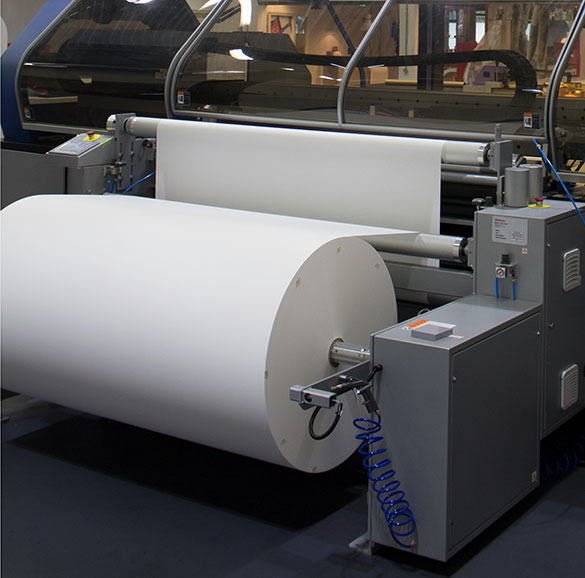

- Unparalleled build quality

ensuring a stabile media feedLooking at the Tiger-1800B MKIII, the first thing to notice is the extreme cast-iron heavy construction which guarantees a vibration-free operation with the highest print quality.

ensuring a stabile media feedLooking at the Tiger-1800B MKIII, the first thing to notice is the extreme cast-iron heavy construction which guarantees a vibration-free operation with the highest print quality.

- Stable printing

on lightweight paper or fabricA sticky belt transport system stands for a stabile media feed, even for lightweight media, to avoid vertical banding.

on lightweight paper or fabricA sticky belt transport system stands for a stabile media feed, even for lightweight media, to avoid vertical banding.

- Ease of operation

with touchscreen on our new MPC (Mimaki Print Controller)With the introduction of our new MPC (Mimaki Print Controller) with touchscreen, preparing your jobs with the Tiger have never been so easy, even when printing from the queue.

with touchscreen on our new MPC (Mimaki Print Controller)With the introduction of our new MPC (Mimaki Print Controller) with touchscreen, preparing your jobs with the Tiger have never been so easy, even when printing from the queue.

Designed to produce a wide range

of materials and applications

Versatility in inks

thanks to high density sublimation and reactive dye inks

Mimaki’s MLSb510 and MLSb520 high-density sublimation ink dramatically improves print quality on polyester. The unique combination of ink and machine technologies achieves cost-effective and eco-conscious direct sublimation printing, and is also available on polyester fabrics with vivid and clear colours. Several black inks are offered to produce subtle differences in shades of black.

With Mimaki’s MLRc500 reactive dye ink, cotton, hemp, and silk are dyed beautifully. These dye inks produce vibrant colours, reproduce a wide colour gamut and have water resistance, light-fastness, and rub-fastness due to dyestuff molecule bonding with the fibres.

For even more confidence

our inks are OEKO-TEX certified

Mimaki inks MLSb510, MLSb520 and MLRc500 for the Tiger-1800B MkIII are ECO PASSPORT by OEKO-TEX® certified. ECO PASSPORT by OEKO-TEX® is a mechanism by which textile chemical suppliers demonstrate that their products are suitable to print skin-friendly clothing and other textiles for end users.

This certificate therefore constitutes an important decision-making element when purchasing inks for textile production.

This printer includes Mimaki Core Technologies that offer the best print quality, maximum productivity and reduced exposure to risks that can delay production. See below list of core technologies that are included in the Tiger-1800 MKIII.

For continued productivity

- Nozzle Recovery System (NRS), to replace missing nozzles

- Automatic Media Feeder (AMF), for optimum media tension

- Degassing

- Automatic Cleaning Function, to keep the print head clean

- Automatic Wiper Cleaner, to keep the wiper clean

- Jam Sensor, to prevent print head damage

For quality printing

- Mimaki Advanced Pass System (MAPS4), to reduce banding

- Waveform Control (WFC), for best possible image sharpness

- Variable Dots Technology (VDT), for smoother gradations

- Mimaki Fine Diffusion (MFD), for smoother colours

| Model | Tiger-1800B MkIII (Direct-to-textile model) | Tiger-1800B MkIII (Sublimation transfer model) | ||

|---|---|---|---|---|

| Print head | 16 printheads (8×2 lines in a staggered layout) | 8 printheads (4×2 lines in a staggered layout) | ||

| Print resolution | 600 / 1,200dpi | |||

| Max. print width | 1,850 mm (72.8″) | |||

| Max. media width | 1,900 mm (74.8″) | |||

| Ink | Type | Reactive: MLRc500 Direct Sublimation: MLSb520 | Sublimation: MLSb510 | |

| Colour | Reactive: C,M,Y,K,Or,Bl,R,Lk Direct Sublimation:Bl,M,Y,K | Bl,M,Y,K | ||

| Loadable ink colour | 8/6/4 | 4 | ||

| Capacity | 10 kg (22 lb) ink tank | |||

| Media core diameter | 2 inch | 3 inch | ||

| Roll diameter | φ400 mm (15.7″) or less | Feeding: φ1000 mm (39.4″) or less Winding: φ500 mm (19.7″) or less | ||

| Roll weight | 100 kg (221 lb) or less | Feeding: 1,000 kg (2,205 lb) or less Winding: 500 kg (1,103 lb) or less | ||

| Interface | Ethernet 10GB-T / USB 2.0 / Removable disk | |||

| Power | Unit: 3Φ 380V ±10%, 50-60Hz ±1% 30A or less Heater: 3Φ 380V ±10%, 50-60Hz ±1% 30A or less | |||

| Operational environment | Temperature: 20 – 25 degC / 68 – 77 degF Humidity: 35 – 65% Rh (Non condensing) | |||

| Dimensions (W×D×H) Appox. | Main | 5,550 x 2,050 x 2,250 mm (219 x 81 x 89″) | ||

| Feeding | 2,250 x 500 x 1,200 mm (89 x 20 x 47″) | 2,750 x 1,800 x 1,350 mm (108 x 71 x 53″) | ||

| Heater / winder | 2,850 x 1,300 x 1,300 mm (112 x 51 x 51″) | 2,900 x 2,400 x 1,350 mm (114 x 93 x 53″) | ||

| Weight | Main | 4,800 kg (10,582 lb) or less | ||

| Feeding | 130 kg (287 lb) or less | 720 kg (1,587 lb) or less | ||

| Heater / winder | 840 kg (1,852 lb) or less | 1,580 kg (3,483 lb) or less | ||

Software RIP

Mimaki’s own developed software TxLink4 comes in the box.

TxLink4

MLSb510

Sublimation ink

High-density sublimation ink dramatically improves print quality on polyester.

Packaging

Colour

Ink type

MLSb520

Sublimation ink

High-density sublimation ink dramatically improves print quality on polyester.

Packaging

Colour

Ink type

MLRc500

Reactive Dye

Mimaki reactive dye ink enables printing on cotton, hemp, silk, rayon, and some kinds of polyester to produce vibrant colours with a high have water resistance and light- and rub-fastness.

Packaging

Colour

C M Y K Or Bl R Lk

Ink type

Request more information

Have a Virtual Coffee