TR300-1850C - Textile Coater

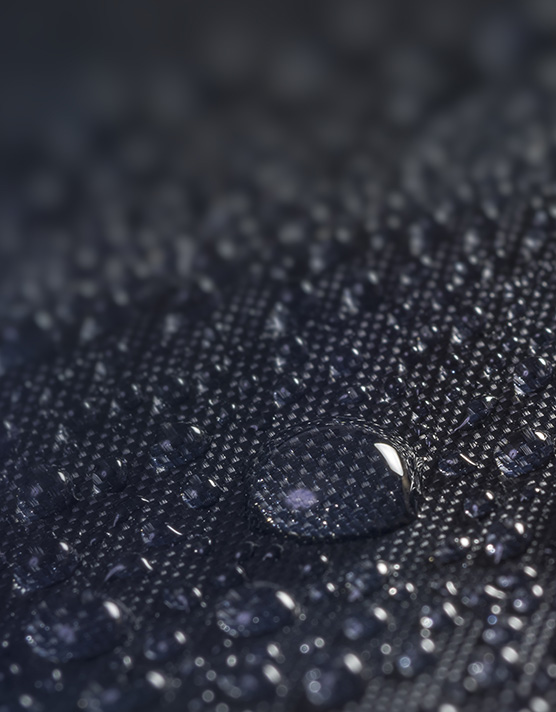

Originally designed for inkjet printing applications, the Mimaki TR300-1850C coater has demonstrated its suitability for the specific treatments required for making mask materials sterile and impermeable.Easy to use, this roll-to-roll pre-treatment unit makes it simple to apply coating on fabrics; from water-soluble antibacterial and antiviral disinfectants to silicone-based products for impermeability, you name it!

Once inserted, the fabric passes through a padder, where it is implanted with the selected chemicals, and in successive phases through squeeze rollers and a dryer, before being rewound into a roll, ready for the next process.